Quality

QUALITY

ASSURANCE OF indiana

ASSURANCE OF indiana

The quality of products and services is a major competitive differentiator. Quality assurance helps us manufacture and transport goods that are defect-free and fulfil the demands and expectations of our consumers worldwide. We make sure in indiana that customers who consume ceramic products from us be satisfied with the quality, which may lead to customer loyalty, repeat purchases, upsell, and advocacy. To ensure the customer satisfaction and product quality from raw material to finished product we perform following tests and inspections.

Sample Matching Inspection:

Sample matching inspection is performed before mass production in Indiana begins with a physical inspection of a test or sample of the developed product prior to production to detect any problems.

During the sample checking process, we make sure in indiana that the physical parameters of the product, such as size, surface, and functional characteristics, should be verified against the Master, design documents, ensuring the quality of the sample meets specified requirements in order to avoid quality problems during our manufacturing process, as well as the reliability and consistency of the manufacturing process and our final product.

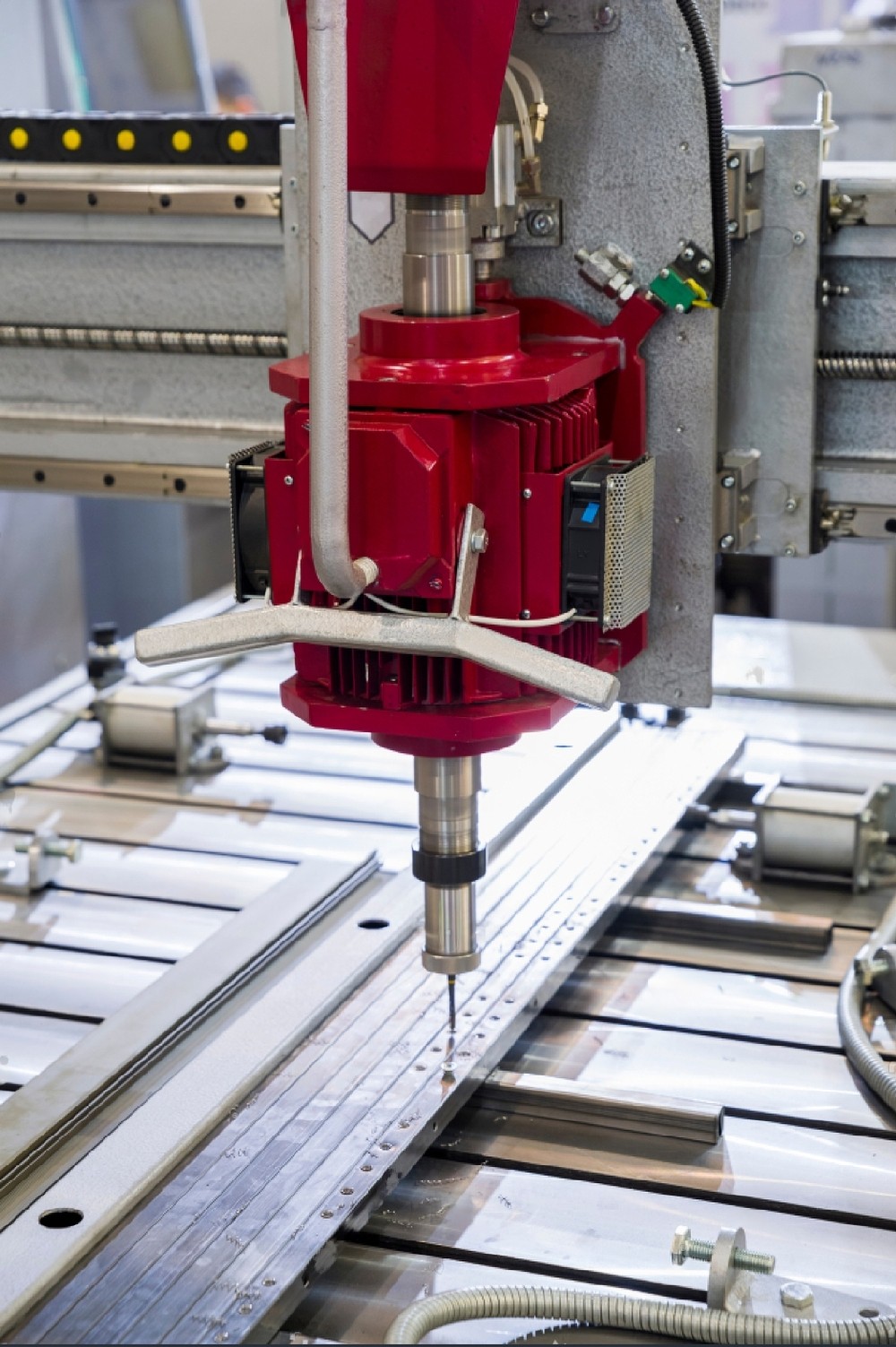

During the Manufacturing Inspection:

During the Manufacturing of fine ceramic products, During Production Inspection (DPI) is taken. DPI is an inspection service performed when 10-15% of units are produced.

During the manufacturing process, to guarantee that the items are produced in accordance with the authorised requirements. This permits us to remedy any problems throughout the subsequent manufacturing process.

Pre-Shipment Inspection:

The Pre-Shipment Inspection (PSI) is a service that inspects our products before they are sent to the buyer or packaged on a pallet. It is one of the most crucial processes in the quality assurance process and the most effective means of inspecting items before they are distributed to buyers.

Indiana Ceramica guarantees that the finished product meets the buyer's standards and is of high quality. It is performed on the final batch of products in accordance with standard Acceptable Quality Limits (AQL) criteria and comprises a thorough assessment of the items, package, and packaging material.

Palletizing witnessing Inspection:

Palletizing witnessing inspection is the activity of inspecting final products and materials that have been palletized for shipping to ensure that they are securely fastened and protected from harm.

Palletizing witnessing inspection is a thorough evaluation of the items and materials, including the wood used to construct pallets for transportation.

At Indiana we thoroughly check the palletized items and supplies, as well as the pallets themselves. The inspection report will contain images and a full analysis of the items and materials.

Container Loading Inspection:

Container Loading Inspections verify that our completed goods are appropriately packed and handled when loaded into containers to ensure safe transit and delivery to the ultimate destination in accordance with international standards. This service is critical for preventing damage while delivery.

Container Loading Inspections entail a thorough assessment of the goods and materials being loaded into containers. We thoroughly check the items and ensure that the container is in good shape, clean, appropriately fumigated, and sealed.

PRODUCT TESTING

Product testing assists us in developing goods that are trustworthy within specific technical parameters. In other words, testing is a vital step for our product development teams to do in order to deliver high-quality, long-lasting goods. Most significantly, product testing may confirm that a product is fit for widespread usage.

Tests conducted before, during and after production

- - Dimensions and surface quality testing

- - Water absorption testing

- - Modulus of rupture/breaking strength testing

- - Impact resistance testing

- - Deep abrasion testing

- - Surface abrasion testing

- - Thermal expansion testing

- - Thermal shock resistance testing

- - Moisture expansion testing

- - Crazing resistance testing

- - Frost resistance testing

- - Chemical resistance testing

- - Stain resistance testing

Adaptable Associations For Evolving Enterprises

Overseas Tie Ups

We have been producing quality tiles for leading companies in the ceramic tile industry for over 12 years, combining stylistic research with overseas OEM requirements to reflect the values of the ‘Made by INDIANA’

Refined design, technical quality: ceramic creations by Indiana embody the values of products.

100% INDIANA EXCELLENCE. Experience, creativity and know-how in the service of porcelain & ceramic manufacturing. Join hands with us to meet special requirements for the quality & quantity.

Plant & Facilities

100% in house production capabilities

Dedicated

Manufacturing Unit

With over 12 years of development experience and production expertise, INDIANA is a leading manufacturer of advanced designs of tiles and engineers these materials for use in a wide area of applications. The current portfolio covers well over 1200+ different products and a wide variety of tiles. At INDIANA, during the manufacturing line, we are always sure to go for quality with a sense of aesthetic beauty to help you make the right choice

We have dedicated plants for special requirements and to cope up with scheduling orders with required sizes respectively.

Customized Product Development

Accepting challenges for design & Huge Quantities

Our ceramic creations are made to measure based on the stylistic demands of markets. We design unique and innovative collections, each exclusively made for the individual client.

Our design, laboratory and production departments all work in synergy in a meticulous production process that is organized and planned around the client’s requirements.

The values of the by INDIANA.

Our Supplier

Quality raw material supplier

We believe that long-term strategic supplier relationship is a key to bring our innovations for the search of best practices towards sustainable development.

We expect our suppliers to meet the highest standards in terms of quality, ethics and sustainability. We support our suppliers in their pursuit of continuous improvement and operational excellence.

We source our raw material from renowned national and international suppliers.

Manufacturing Process

WELL-CHOSEN TILES INTENSIFY THE COLOUR OF THE WALLS & FOOR AND ALSO ENHANCE THE LIGHTING OF THE SPACE. SINCE DESIGNING A BUILDING IS A SKILLED ART, IT IS IMPORTANT TO ACKNOWLEDGE THE EXPERTISE THAT DOES A GREAT JOB IN MANUFACTURING LONG-LASTING, DURABLE AND ARTISTIC-LOOKING TILES.